How to Choose the Right Construction Tools for Your Project?

Choosing the right construction tools for your project is crucial. The success of your work often depends on them. With countless options available, making a choice can feel overwhelming. You might find yourself staring at a wall of tools, unsure which ones will best meet your needs.

Different projects require different tools. A basic renovation might need simple hand tools. On the other hand, complex tasks demand specialized equipment. Misjudging your needs can lead to wasted time and money. It is essential to understand the scope of your project and assess your skills.

Additionally, consider the quality of construction tools. Cheaper options may seem tempting. However, they often lead to more issues down the line. Investing in reliable tools can save you headaches in the future. Sometimes, asking for recommendations can help guide your choice. Be open to feedback but remain critical of what others suggest.

Understanding the Types of Construction Tools Available

Choosing the right construction tools for your project requires understanding their types. Each tool serves a specific purpose, and knowing these can save time and effort. Hand tools, like hammers and screwdrivers, are essential for small-scale tasks. They are easy to use and require no electricity. However, they may not be sufficient for larger projects.

On the other hand, power tools, such as drills and saws, can be a game-changer. They speed up the work but come with risks if misused. Always consider safety features when selecting power tools. For example, some drills have adjustable speeds for different materials. Yet, newcomers often overlook these details.

Construction equipment, like excavators and cranes, plays a crucial role in major jobs. They manage heavy lifting and significant tasks with ease. Still, operating such machinery demands training and experience. Without proper knowledge, accidents can occur. Reflecting on past mistakes in tool selection can guide future choices for better project outcomes.

Evaluating the Scale and Scope of Your Construction Project

Evaluating the scale and scope of your construction project is crucial. Start by defining the project size. A small renovation needs different tools than a large structural build. Consider whether the project is residential or commercial. The complexity can vary significantly. Think about the materials you'll be using. Will you need heavy machinery, or will hand tools suffice?

Next, assess the timeline and budget. Do you have enough resources for high-quality tools? If funds are limited, it may be wise to rent equipment. This could save money upfront. However, remember that rental tools may not suit every project’s needs. You might face delays if they aren't available when you need them.

Lastly, don’t forget about safety. Larger projects often require specialized tools. This can seem overwhelming. But attention to detail is key. If you're unsure, seek advice from experienced professionals. It’s okay to admit when you need help. This can lead to better decisions and smoother execution.

How to Choose the Right Construction Tools for Your Project?

| Tool Type | Recommended Scale of Project | Key Features | Typical Applications |

|---|---|---|---|

| Cordless Drill | Small to Medium Projects | Battery-operated, Lightweight, Various Speed Settings | Drilling Holes, Driving Screws, DIY Tasks |

| Circular Saw | Medium to Large Projects | Electric, Adjustable Blade Depth, Safety Features | Cutting Wood, Plywood, and Other Sheet Materials |

| Excavator | Large Construction Sites | Heavy-duty, Hydraulic Operation, Various Attachments | Digging, Demolishing, Lifting Heavy Materials |

| Level | All Project Sizes | Laser or Bubbled, Easy to Use, Lightweight | Checking Horizontality and Verticality |

| Concrete Mixer | Medium to Large Projects | Motorized, Portable, Adjustable Mixing Speed | Mixing Concrete for Foundations and Structures |

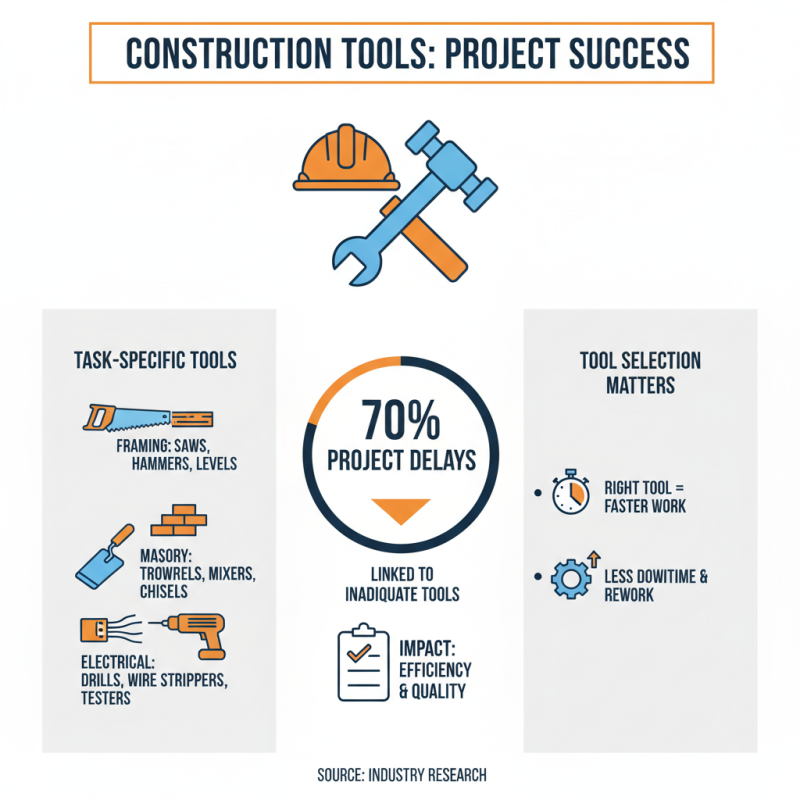

Identifying Essential Tools for Different Construction Tasks

Choosing the right construction tools is crucial for project success. Different tasks demand specific tools. For instance, framing requires saws, hammers, and levels. According to industry research, about 70% of delays are linked to inadequate tools. This statistic highlights the importance of proper tool selection.

For demolition tasks, pry bars and sledgehammers are necessary. These tools help workers efficiently tackle tough materials. A report from the Construction Industry Institute indicates that effective tool use can improve productivity by 30%. Yet, many workers overlook tool quality. This can lead to injuries or project delays.

When it comes to finishing work, items like nail guns and trowels come into play. These tools enhance precision and speed. However, using the wrong tool can result in poor craftsmanship. In fact, poor tool choices can impact finished quality. Reflecting on past projects may reveal overlooked aspects of tool selection.

Budget Considerations When Selecting Construction Tools

When selecting construction tools, budget considerations play a significant role. According to a recent industry report, up to 40% of project costs can be attributed to tools and equipment. Therefore, understanding how to allocate funds effectively is essential. A strategic approach involves balancing quality and affordability. Opting for high-quality tools ensures durability and reliability. However, this might lead to initial higher costs.

Many projects may overlook secondary expenses related to tool maintenance. A study found that poorly maintained tools account for 15% of project delays. In light of this, budgeting should not end with the initial purchase. Setting aside funds for regular tool maintenance is vital for long-term savings. Additionally, purchasing used or rented tools can be a budget-friendly alternative. This option allows for flexibility without compromising on tool functionality.

It’s essential to reflect on project needs. Not every tool is necessary for every task. A well-structured budget highlights the importance of prioritizing required tools over optional ones. Investing in a few high-quality items may be wiser than buying a broader range of cheaper alternatives. This approach can ultimately lead to better project outcomes and fewer frustrations throughout the construction process.

Safety Features and Ergonomics in Choosing Construction Tools

When choosing construction tools, safety features should be a priority. Ergonomics plays a vital role in preventing injuries. Tools that are uncomfortable lead to fatigue. This can impact the quality of your work. Look for tools with padded grips. They reduce strain on your hands. Lightweight tools are easier to handle. This is crucial during long hours on-site.

Consider the safety mechanisms of each tool. A tool with a guard or automatic shut-off can prevent accidents. Check that the blade or cutting edge is well-protected. This reduces the risk of accidental injury. Be mindful of the tool's weight distribution. An awkward balance can cause mishaps. Pay attention to how it feels in your hand. If it feels off, it might be a sign to rethink your choice.

In addition to comfort, consider how often you use a tool. Frequent use means more wear and tear. Regular checks can help catch potential safety issues. It's easy to overlook this during busy projects. Reflect on your experiences with different tools. Did any cause discomfort or pain? Identify those, and learn from them. This awareness can guide your future purchases.

Related Posts

-

Why Are Rigging Tools Essential for Safe Lifting and Load Handling?

-

Top 10 Cutting Tools Every DIY Enthusiast Should Have in Their Toolkit

-

What is the Best Materials and Tools for Sustainable Building Projects?

-

Best 10 Various Tools for Digital Productivity and Efficiency?

-

Why You Should Upgrade to the Latest Tools for Your DIY Projects

-

Top 10 Best Building Tools for Every DIY Enthusiast?