What is the Role of Materials Tools in Modern Technology?

In the fast-paced world of modern technology, materials tools play a vital role. These tools encompass a variety of instruments and technologies used to manipulate materials. Their importance cannot be overstated. From manufacturing to construction, materials tools shape our daily lives.

Consider the impact of 3D printing. It revolutionizes how we create objects. Yet, it raises questions about sustainability and waste. Not every material used in these tools is eco-friendly. Similarly, advanced cutting tools enhance precision in machining, but they can be costly and require training.

Moreover, the evolution of materials tools often leads to unintended consequences. While we strive for efficiency, over-reliance on technology can lead us to overlook fundamental skills. It's crucial to reflect on how we use these tools. Balancing innovation and traditional craftsmanship remains a challenge for the industry.

The Evolution of Materials Tools in Technological Development

The evolution of materials tools has significantly influenced technological development over the centuries. Initially, early humans relied on simple tools made from stones or wood. These rudimentary implements enabled basic tasks such as cutting and hunting. As societies advanced, the discovery of metals transformed tools, leading to greater efficiency and new capabilities. The shift from bronze to iron tools marked a pivotal moment in history. Iron tools proved more durable and effective, allowing civilizations to grow.

In modern times, the manipulation of materials has reached unprecedented levels. Advanced composites and synthetic materials enable lighter and stronger tools. These innovations contribute to various fields, such as aerospace, medicine, and construction. However, not all advancements are flawless. The environmental impact of certain materials raises concerns. Mining and production processes can be harmful. There is a delicate balance between technological advancement and sustainability.

Materials tools continue to evolve, reflecting society's changing demands. 3D printing, for example, enables rapid prototyping, but poses questions. How sustainable are these new materials? What about waste? These are problems worth examining. Innovation carries responsibility. As we create tools to improve lives, we must also reflect on our choices and their impacts on the world around us.

Key Types of Materials Tools Used in Modern Technology

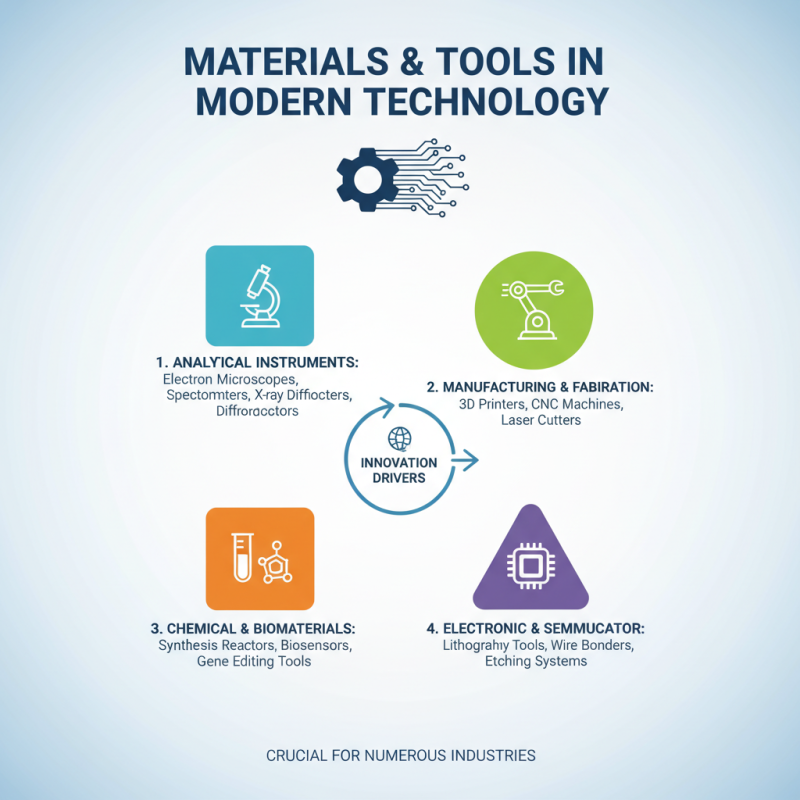

Materials tools play a crucial role in modern technology. These tools vary widely, influencing numerous industries. Here are some key types used today.

One major category includes cutting tools. They are essential in manufacturing. Such tools are used to shape materials like metal and wood. Precision is critical. A small mistake can lead to significant waste. Choosing the right cutting tool matters.

Another important type is measuring tools. These tools ensure quality control. They assess size, weight, and dimensions. Poor measurements can result in defective products. Relying solely on visual estimates is risky. Always double-check with measuring tools.

Tips: Invest in high-quality measuring tools. They can save time and resources. Regularly maintain cutting tools for longevity. Replace worn-out tools promptly. This approach minimizes errors and enhances efficiency. Remember, small tools can have a big impact.

The Impact of Advanced Materials on Tool Performance

The performance of tools in modern technology heavily relies on the advancement of materials used in their construction. Recent studies show that tools made with advanced materials can last up to 50% longer compared to traditional options. For example, high-strength composites and specialized alloys provide enhanced durability and resistance to wear. These materials can endure extreme conditions, which improves overall tool efficiency.

Tips: Always choose tools based on the specific materials they are constructed from. Consider factors like weight, strength, and resistance levels when making a decision.

Despite these advancements, there are still challenges. Not all materials perform consistently under different environments. For instance, some high-performance materials may become fragile at low temperatures. This inconsistency can lead to unexpected failures. In these cases, optimizing the selection process becomes crucial for users.

Tips: Conduct regular assessments to understand how different materials behave under varying conditions. It is important to learn from failures to improve future performance. Research reports indicate that a systematic approach to material selection can reduce tool failure rates significantly.

Applications of Materials Tools Across Various Industries

Materials tools play a crucial role in various industries today. In manufacturing, these tools enhance precision. For instance, advanced cutting tools allow for the creation of intricate designs with minimal waste. However, not all materials perform as expected. Some may wear out too quickly, leading to delays and increased costs.

In the construction industry, material tools are essential for building safe and durable structures. Concrete mixers and laser levels help ensure accuracy. Yet, materials may not always meet ideal standards. This inconsistency can result in structural weaknesses. Engineers must constantly test and adapt their choices.

Electronics benefit significantly from advanced materials tools. Soldering irons and micro-manipulators enable detailed assembly of devices. Still, the reliance on specific materials can lead to challenges. For example, heat sensitivity can compromise functionality. Continuous innovation is vital to address these issues and improve outcomes.

Future Trends in Materials Tools and Their Technological Implications

The future of materials tools is shaping modern technology in profound ways. According to a report by the Global Industry Analysts, the market for advanced materials is projected to reach $1 trillion by 2025. This growth is driven by the need for sustainable solutions and innovative applications across industries. Advanced materials include composites, nano-materials, and smart materials. Each has unique properties that enhance performance and efficiency in various technologies.

Emerging trends showcase a shift towards automation and AI in material creation. The adoption of AI technologies can optimize design processes. Recent studies reveal that AI-driven design processes can reduce production time by up to 30%. While this revolutionizes manufacturing, challenges remain. Not all materials meet sustainability standards. The dilemma lies in balancing innovation with environmental responsibility. As tech progresses, additional scrutiny is necessary to ensure that materials meet both performance and ecological criteria.

Furthermore, recycling and reusability are becoming focal points. With growing waste from conventional materials, industries seek alternatives. Reports indicate that only 20% of plastic is recycled globally. This statistic highlights the urgency for better solutions. Innovations in materials tools must not only focus on performance but also on creating a circular economy. As we venture into the future, the implications of these developments are vast and complex.

What is the Role of Materials Tools in Modern Technology? - Future Trends in Materials Tools and Their Technological Implications

| Dimension | Description | Impact on Technology | Future Trends |

|---|---|---|---|

| Material Selection | Choosing appropriate materials for specific applications | Improves product performance and efficiency | Increasing use of smart materials |

| Manufacturing Techniques | Methods such as 3D printing and CNC machining | Enhances precision and reduces waste | Greater automation and integration of AI |

| Sustainability | Utilizing eco-friendly materials and processes | Reduces environmental impact | Focus on circular economy approaches |

| Tool Development | Innovative tools for material testing and processing | Increases reliability and accuracy of material properties | Advancements in nanotechnology tools |

| Data Analysis | Using data analytics for materials performance | Facilitates predictive maintenance and optimization | Integration of big data and machine learning |

Related Posts

-

What is the Best Materials and Tools for Sustainable Building Projects?

-

How to Choose the Right Building Materials and Tools for Your Projects

-

Top 10 Safety Tools You Need for Enhanced Protection and Peace of Mind

-

Top 10 Cutting Tools Every DIY Enthusiast Should Have in Their Toolkit

-

10 Essential Tips for Choosing the Right Drill Tools for Your Projects

-

Top 10 Essential Tools for Building Your Dream Projects Efficiently