Top 10 Cutting In Tools for Precision and Efficiency

The accuracy and efficiency of any cutting project significantly hinge on the choice of cutting in tools. In a world where precision is paramount, the right tools can make all the difference in achieving flawless results. Whether you're a professional contractor or a passionate DIY enthusiast, understanding the various options available can enhance your craftsmanship and streamline your workflow. From intricate detailing to clean edges, investment in quality cutting in tools is essential for producing exceptional work.

This article delves into the top 10 cutting in tools designed to help you elevate your projects. Each tool brings its own unique features and capabilities, catering to different cutting needs and materials. By exploring these essential instruments, you'll discover which tools can not only improve your efficiency but also boost the overall quality of your finishes. Join us as we guide you through this curated selection, ensuring you have all the information needed to equip yourself with the best cutting in tools for any task at hand.

Understanding Cutting In Tools: Definition and Importance

Cutting in tools are essential instruments used in various industries, including construction, woodworking, and manufacturing. These tools are specifically designed to create precise and clean edges, enabling professionals to achieve the desired aesthetics and functionality in their projects. Understanding the definition of cutting in tools is crucial; they are instruments that expertly trim, shape, or configure materials with accuracy. This precision is vital for ensuring that subsequent processes, such as assembling or finishing, can be executed flawlessly.

The importance of cutting in tools cannot be overstated, as they significantly influence the efficiency of work processes. High-quality cutting tools reduce material waste, minimize the need for rework, and improve overall productivity. Moreover, the accuracy provided by these tools contributes to higher-quality end products, which can enhance customer satisfaction and bolster a company's reputation. By investing in the right cutting in tools, professionals can not only enhance their craftsmanship but also optimize their workflow, making these tools invaluable assets in any project.

Key Features of Precision Cutting Tools to Enhance Efficiency

When it comes to precision cutting tools, several key features can significantly enhance efficiency in various applications. One essential characteristic is the material from which the tool is made. High-quality materials like carbide or titanium can provide superior durability and sharpness, allowing for cleaner cuts and reducing the need for frequent replacements. Furthermore, tools with ergonomic designs can contribute to better user comfort, minimizing fatigue during extended use and improving overall productivity.

Tip: Always consider the weight and balance of the tool you are using. A well-balanced cutting tool not only makes the job easier but also helps you maintain accuracy during intricate cuts.

Another crucial feature is adjustable cutting depth settings. Tools that allow for precise depth adjustments enable users to tailor their cutting strategies to specific materials or tasks. This can lead to more versatile applications and prevent damage to workpieces. Additionally, tools with built-in safety mechanisms enhance operational confidence and foster a safer working environment.

Tip: Regularly maintain your cutting tools to ensure optimal performance. Simple practices like cleaning after each use and checking for wear can prolong the life of your tools and ensure they continue to perform efficiently.

Top 10 Cutting In Tools for Precision and Efficiency

| Tool Name | Cutting Type | Material Compatibility | Key Features | Efficiency Rating |

|---|---|---|---|---|

| Rotary Cutter | Rotary Cutting | Fabric, Paper | Ergonomic Grip, Adjustable Blade | 9/10 |

| Precision Knife | Precision Cutting | Paper, Thin Plastic | Fine Point, Replaceable Blades | 10/10 |

| Electric Scissors | Electric Cutting | Fabric, Leather | Automatic, Quick Release Blades | 8/10 |

| Laser Cutter | Laser Cutting | Wood, Acrylic, Metal | High Precision, Customizable Settings | 10/10 |

| Utility Knife | General Cutting | Cardboard, Plastic | Retractable Blade, Safety Lock | 7/10 |

| Cutting Mat | Self-Healing Cutting | Various Materials | Durable, Grid Lines for Accuracy | 9/10 |

| Die Cut Machine | Die Cutting | Paper, Cardstock | Interchangeable Dies, User-Friendly | 8/10 |

| Circular Saw | Circular Cutting | Wood, Metal | Powerful Motor, Depth Adjustment | 9/10 |

| Snips/Shears | Shearing | Metal, Fabric | Heavy Duty, Comfortable Handles | 8/10 |

| Chisel | Chiseling | Wood, Soft Metals | Precision Edge, Durable Material | 9/10 |

Top 10 Cutting In Tools: Overview and Selection Criteria

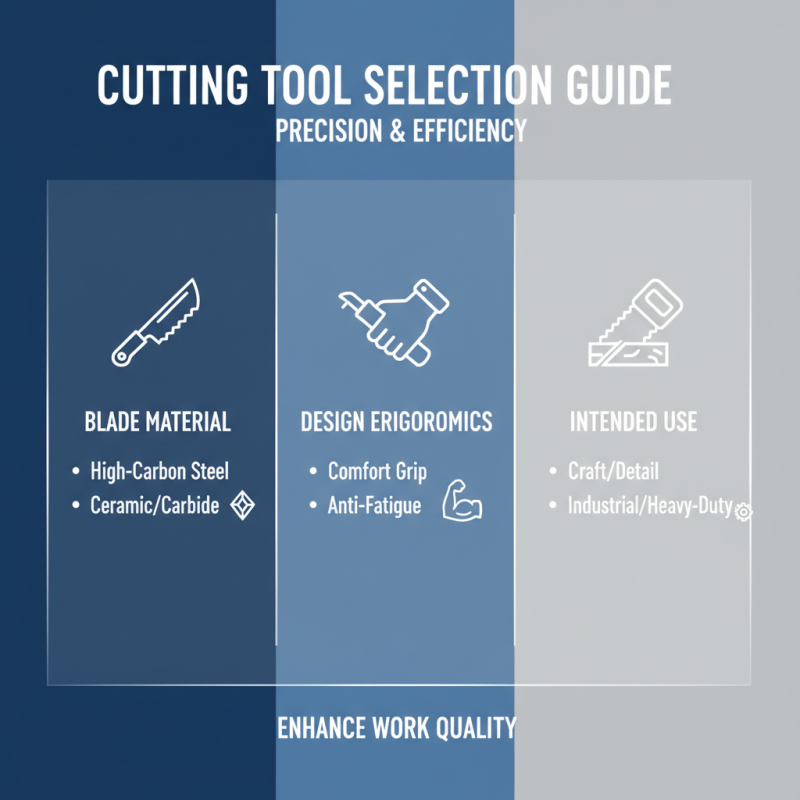

When it comes to selecting cutting in tools, precision and efficiency are paramount. Understanding the essential features and specifications can greatly enhance your work quality. Key criteria include the blade material, design ergonomics, and the tool's intended use. High-quality blades tend to offer better cutting performance, while ergonomic designs minimize hand fatigue, enabling you to work longer and more efficiently.

Tip: Always consider the specific material you'll be cutting through when selecting a tool. For example, some blades are better suited for harder materials, while others excel in softer surfaces. This knowledge will help you avoid unnecessary wear and tear on your tools and allow you to achieve cleaner cuts.

Additionally, ease of maintenance is another crucial factor. Tools with replaceable blades or those that are easy to clean will not only save you time but also enhance longevity. A well-maintained tool ensures consistent performance and cuts down on the need for frequent replacements.

Tip: Keep your cutting tools organized and accessible. A dedicated storage solution can prevent damage and ensure that you can quickly find the right tool for the job, leading to more efficient work processes.

Applications of Cutting In Tools Across Various Industries

Cutting in tools play a crucial role in numerous industries, enhancing both precision and efficiency in various applications. In manufacturing, for example, cutting in tools are extensively used for machining operations such as drilling, milling, and turning.

According to a report by the International Federation of Robotics, the introduction of advanced cutting tools and robotics in production lines has improved efficiency by up to 30%, illustrating the significant impact of precise cutting tools in reducing overhead and waste. This efficiency not only boosts productivity but also enhances product quality, making cutting tools indispensable across the manufacturing sector.

In the construction industry, the applications of cutting in tools can be observed in activities ranging from installing drywall to precision cutting of materials such as metal and wood. A recent study by the Construction Industry Institute indicated that the use of high-quality cutting tools can reduce project completion times by an average of 15%, primarily due to the improved speed and accuracy of cuts.

Furthermore, in the automotive industry, cutting tools are essential in processes like engine block machining, where precision is vital for the performance and safety of vehicles. As reported by the Society of Manufacturing Engineers, the integration of innovative cutting technologies has not only reduced scrap rates but also extended tool lifespan, significantly contributing to cost savings and sustainability efforts in the industry.

Maintenance Tips for Prolonging the Lifespan of Cutting Tools

To ensure the longevity and reliability of cutting tools, regular maintenance is crucial. One fundamental practice is keeping tools clean and free from debris. After each use, it is advisable to wipe off any accumulated dust or residue that may affect cutting performance. This not only prevents rust and corrosion but also ensures that the cutting edges remain sharp and effective, enhancing overall efficiency.

Another essential aspect of maintenance involves proper storage. Tools should be stored in a dry environment, ideally in protective cases or trays that prevent dulling and accidental damage. Additionally, periodic sharpening and alignment of cutting edges help maintain precision. Using appropriate sharpening techniques tailored to the specific tool type ensures that they retain their desired cutting angles, contributing significantly to their lifespan. Adopting these maintenance practices will ultimately lead to improved cutting performance and a reduction in the frequency of tool replacements.

Top 10 Cutting Tools for Precision and Efficiency

This chart illustrates the durability of the top 10 cutting tools measured in hours. Understanding the longevity of each tool helps in selecting the right one for precision and efficiency.

Related Posts

-

2025 Top Cutting Tools Trends and Technologies Transforming the Industry

-

10 Essential Power Tools Every DIY Enthusiast Should Own for Home Projects

-

Why You Should Upgrade to the Latest Tools for Your DIY Projects

-

Top 10 Essential Tools for Building Your Dream Projects Efficiently

-

Why You Should Invest in Power Tools for Your DIY Projects and Home Improvements

-

How to Choose the Right Building Materials and Tools for Your Projects